Size Matters – Picking the Right Equipment and Services

Embarking on the design of a project with a swimming pool is a thrilling challenge, especially if it’s your first time. Everyone loves a challenge, but where does one begin? In our perspective, it’s crucial to start by understanding the equipment required and its role within the system. Equally important is recognizing that these equipment pieces do not operate in isolation; they require services, be it for powering, water supply, or effective drainage.

This article delves into the primary equipment components and their functions, shedding light on the essential service requirements for the plant room. We’ll refrain from discussing how to size them at this point (an attempt at that turned into a hefty 10-page technical document). If you’re interested in learn more about sizing equipment, stay tuned for upcoming articles where we’ll provide a technical explanation of how to do this.

The Right Equipment

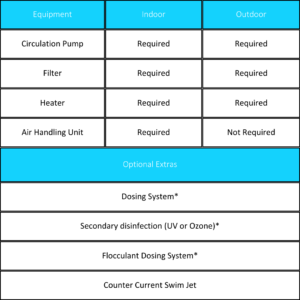

Now, let’s examine the equipment typically designated for a swimming pool. The list below highlights what we consider the main pieces of equipment required within a swimming pool system.

While this list doesn’t cover every piece of equipment necessary for a swimming pool, it highlights the most crucial components, offering a solid understanding. For those envisioning a more specialized pool, additional equipment becomes imperative. Take, for instance, a pool with an integrated spa—it demands a complete secondary plant setup. This entails a dedicated circulation pump, a filter (sometimes larger than a standard pool filter), a heater, and specialized spa equipment like a boost pump and air blower.

Circulation Pump

The swimming pool circulation pump is a pivotal component in the water circulation and filtration system. Its primary role is to propel water through the pool’s filtration system, ensuring a continuous filtration process and proper circulation.

In the UK, these pumps are typically sized in Horsepower (HP) rather than kilowatts (kW). Circulation pumps constitute one of the most substantial electrical loads within the plant room. Consequently, it’s advisable for architects, or anyone involved in planning a plant room, to have a basic understanding of estimating the required size and power for these pumps.

Filter

The swimming pool filter is a vital element in the pool’s circulation system, dedicated to eliminating impurities and debris from the water to maintain a clean and safe environment for swimmers.

Filters are quantified by their filter surface area (m2), and this measurement corresponds to a diameter. This information proves valuable not just in sizing a plant room but also in discussing the essential services needed for the project.

There are various factors to consider in filter discussions—such as diffuser style, filter media bed depth, and water collector type. These specifics are not the focus of today’s blog. They will be covered in another article, in sure.

In the UK, two main types of filter systems prevail: Multimedia filters and Cartridge filters. Personally, I advocate for reserving cartridge filters for domestic spas and hot tubs, excluding them from use in swimming pools, especially commercial ones. Henceforth, my references will exclusively pertain to multimedia filters. Although Diatomaceous Earth (DE) filters exist, they are quite rare, and their discussion is beyond the scope of this blog.

Heater

Swimming pool heaters serve a simple yet crucial purpose – they are devices designed to elevate water temperature, enhancing comfort for swimmers and extending the swimming season. Various types of pool water heaters exist, including the electric immersion heater, low-pressure hot water (LPHW) tube heat exchanger, LPHW plate heat exchanger, dedicated heat pump, and oil and gas boiler.

Notably, some heat exchangers are integrated within air handling units, proving advantageous in space-constrained environments.

While architects need not choose the specific heater model, they often specify the services required for the plant room. For heaters relying on LPHW as their heat source, considerations such as temperature, connection size, and flow rates become pivotal. On the other hand, electric immersion heaters pose a substantial electrical load, demanding attention from the architect.

Furthermore, if a dedicated air source heat pump is the preferred heater, it introduces a significant electrical load and specific spatial requirements, necessitating thoughtful consideration during the initial design stages.

Air Handling Unit

The Air Handling Unit (AHU) plays a pivotal role in regulating the environment within the swimming pool hall. Given the harsh conditions on both occupants and the pool hall’s structure, the AHU is responsible for maintaining optimal air temperature, relative humidity, and introducing the necessary fresh air into the pool area.

While this blog post refrains from delving deeper into the specifics of HVAC (Heating, Ventilation, and Air Conditioning), it emphasizes the importance of considering the AHU and its requirements, particularly in terms of drainage and LPHW supply requirements.

Stay tuned for Part 3 of this series, titled “Keeping It Fresh – Air Systems, Ducts, and the Environment,” where we will delve further into these critical aspects.

*All these pieces of equipment are recommended for a commercial swimming pool.

Services Required

Now, onto the section everyone eagerly anticipates: the required services. The pool plant system relies on various services to ensure the equipment can functions. Let’s now have a brief look at the services required and what they do.

LPHW

Low-Pressure Hot Water serves as a heat source for both the AHU and the swimming pool water heat exchanger (unless an alternative pool water heating system has been chosen). This heat source typically comes from two primary sources: a gas boiler or an electric heat pump with a buffer tank. Both methods are suitable for swimming pool applications; however, understanding the temperature difference in the LPHW they provide is crucial, as it impacts heat transfer within the swimming pool water heater and the AHU.

The LPHW supply temperature from a gas boiler system ranges from 70 – 80°C, whereas the supply temperature from an heat pump buffer tank, is notably cooler, around 45 – 55°C. Due to this temperature variance between the two sources, achieving the required level of kW for the pool water heater and the AHU will necessitate a substantially larger flow rate from the heat pump system. I will delve into the calculation of these flow rates in another article, emphasizing that it’s not as straightforward as swapping one unit for another.

Drainage

Effective drainage is a critical element in the overall design of a swimming pool building. Significant water loss occurs during the weekly operation of the pool, necessitating proper drainage solutions. Various drains are essential to incorporate into the design and installation process, including:

– Backwash Drain

– Pool Overflow Drain

– AHU Condensate Drain

– Auto Water Top Up Drain (if installed)

– Filter Drain (if installed)

While this list is not exhaustive, it does highlight a crucial drain: the Backwash Drain. This drain is utilized during filter cleaning, specifically targeting the filter media within the filters. During backwashing, the water flow through the filter is reversed, allowing the filter media bed to expand and release contaminants trapped within. This water flow is directed down the backwash drain.

However, it’s crucial to note that the backwash drain must be independent of all other drains and should be appropriately rated to handle the associated flow volume and velocity. Incorrectly sized drains pose the risk of backwash discharge returning up into the filter and potentially re-entering the pool. This scenario would present a severe contamination issue, as the filter bed contains pathogens and bacteria unsuitable for swimming.

I will delve into the specifics of calculating the drain sizes in a subsequent article.

Water Supply

Ensuring a water supply into a swimming pool plant room might seem like an obvious consideration, yet it is a service often overlooked during the building design phase. Consequently, pool operators frequently resort to improvisation, such as using a garden hose to replenish water levels, especially after backwashing. The installation of an Auto Water Top-Up (AWTU) unit can significantly simplify the lives of pool operators. Additionally, the importance of dilution in maintaining high water quality cannot be overstated.

To determine the required water supply, it is essential to consider three factors:

1. Backwash: The volume of water lost during a single backwash cycle.

2. Dilution: The amount of fresh water needed per bather to mitigate water quality issues.

3. Evaporation: The volume of water lost due to evaporation.

While domestic pools might achieve sufficient dilution during the backwash process, commercial pools often require additional dilution. Each of these factors necessitates its own refill flow rate, with the backwash refill flow rate typically exceeding that of the other two factors. This flow rate dictates the mains water supply needed for the plant room.

A crucial point to bear in mind during the installation of a mains water supply into a plant room is that the mains water directly connects to the chemically treated pool water system. This connection is not permitted by water authorities, necessitating the installation of an air gap and overflow.* This precaution ensures that in the event of a valve failure within the AWTU system, preventing water siphoning back into the mains water source. This air gap is known as a Category 5 type AB, often referred to as CAT 5.

I will elaborate on the calculation process in a subsequent article.

*Please consult with your local water authority.

Electrical Supply

Addressing the electrical supply is a critical aspect of any swimming pool project to avoid issues such as equipment tripping RCDs within the consumer unit due to an incorrectly rated supply current. While architects may not need an in-depth understanding of every electrical detail, a basic comprehension of the electrical equipment within the plant room and their potential supply requirements is advisable.

Here’s an overview of common electrically powered items in swimming pool plant rooms:

1. Circulation Pumps: These are significant electrical components, with even small pumps drawing around 0.5kW. Domestic pumps are often single-phase, but larger pumps for commercial use may require three-phase power.

2. Air Handling Units: Although one of the largest pieces of equipment, their proportional electrical power consumption is relatively small compared to circulation pumps. They can be either single-phase or three-phase and may draw a substantial current, necessitating correctly rated cables and MCBs.

3. UV Systems: These units have moderate electrical consumption. For example, the power consumption of an Advanox UV system (Pool AOP 80) for an 80m3 pool is around 140W.

4. Electric Heaters (Immersion Heaters or Air Source Heat Pumps): Immersion heaters draw high power ratings, while Air Source Heat Pumps have lower requirements due to their coefficient of performance. Both can be single-phase or three-phase.

5. Swimming Pool Lights: Modern LED pool lights are more energy-efficient, drawing significantly less power compared to traditional halogen lights. Even large commercial LED pool lights might only draw around 30W per bulb.

6. Dosing Systems: Dosing pumps typically have a smaller power load, similar to modern pool lights, ranging from 20 to 50W per pump.

Again, this list is not exhaustive, and the specific requirements of each plant room will vary. Architects should consider these factors to ensure proper electrical planning and avoid potential issues during the installation and operation of the swimming pool equipment.

Internet Connection:

The consideration of remote monitoring and control is often left as a last-minute decision for the plant room, typically prompted by a client’s late realization of its potential benefits. This aspect, although sometimes overlooked, can play a crucial role, especially in commercial settings where remote access is deemed important.

While there may be concerns about providing pool owners with unrestricted access to equipment settings, particularly in domestic setups, the importance of remote monitoring in commercial sites cannot be understated. The ability to monitor and control equipment remotely can contribute to efficient operation, timely issue resolution, and overall system management.

When implementing remote monitoring, the following considerations may be relevant:

1. Network Cabling: Large data packets are not typically exchanged between swimming pool equipment, simplifying network cabling requirements. The primary consideration is the length of the cable required to reach the main switch. Hard-wired connections are recommended for reliability.

2. Wireless Options (Wi-Fi, Mobile Data): While Wi-Fi and mobile data are alternatives, plant rooms often have poor signal reception, and interference generated by equipment may further degrade signal quality. As a result, hard-wired connections are preferred for more stable and reliable communication.

3. Security Concerns: Given that remote access involves network connectivity, security should be a paramount concern. Implementing secure communication protocols and access controls is essential to prevent unauthorized access or tampering.

4. Client Preferences: Understanding the client’s preferences regarding remote monitoring is crucial. Some may prioritize real-time access and control, while others may not see it as a necessity. Tailoring the system to meet the client’s specific requirements is key.

While there may be reservations about providing remote control capabilities, especially in domestic settings, addressing security concerns and emphasizing the potential benefits in terms of system efficiency and issue resolution can help clients make informed decisions about incorporating remote monitoring into their swimming pool plant room.

Conclusion

For architects and anyone involved in pool construction, a solid understanding of the plant room equipment and required services is crucial for a successful project. Avoiding last-minute surprises, such as realizing the need for a water supply or electrical requirements, is key to ensuring a smooth process.

Imagine building a top-notch swim school in Huddersfield, only to face issues with circulation pumps due to a missed three-phase electrical supply. These are the challenges we aim to prevent, ensuring that pool projects run seamlessly, with minimal headaches and unexpected calls to utility providers.

In our next article, we’ll delve into more details about Air Systems, Ducting, and the Environment. Additionally, we’ll provide “How To” cheat sheets with calculations for pump sizing, filter dimensions, pipe sizing, and more, complete with worked examples and equations.

Selecting the appropriate equipment and rating the services correctly involves more than meets the eye. This blog is part 2 of a series aimed at helping architects deliver exceptional pool projects. If you’ve encountered other challenges or have insights into equipment and service selection, share them with us. We’re all ears and eager to explore more in our upcoming posts. Get in touch with Pool Logic at enquiries@poollogic.co.uk.