So, you’ve designed your pool perfectly, right?… You’ve added the correct number of return inlets, you’ve used the optimal pipe size, you’ve calculated the most appropriate circulation flow rate for your required pool use, you’ve purchased the best tiles in existence, and everything looks spectacular. But oops, there’s a problem. Once you look a little deeper you start to notice that not everything is kosher.

You try and backwash your filter and, oh, the drainage backs up and you have waste water all over your plant room floor; you fancy a nice cheeky massage, so you turn on your Fluvo Water Cannon and, oh, the electrics cut out; your cover keeps jamming in the pit envelope, oh, your water level is too low; you want to remotely check your pool temperature, oh, 404 Not Found – the internet connection keeps dropping.

It may seem like you have nailed everything, but fundamentally you’ve neglected one major design area – Services. Trust me, this is all too common. Hopefully, after reading this article you will have a better understanding of the key services involved in a swimming pool project and why they are important.

When I’m working on a new project, I always look at 5 key design areas that come under the banned of services.

- Drainage

- Mains Water

- Electrical Supply

- LPHW Supply

- Ethernet Connection

In this month’s Design Top Tips, we are going to discuss each of these areas in detail, starting with drainage.

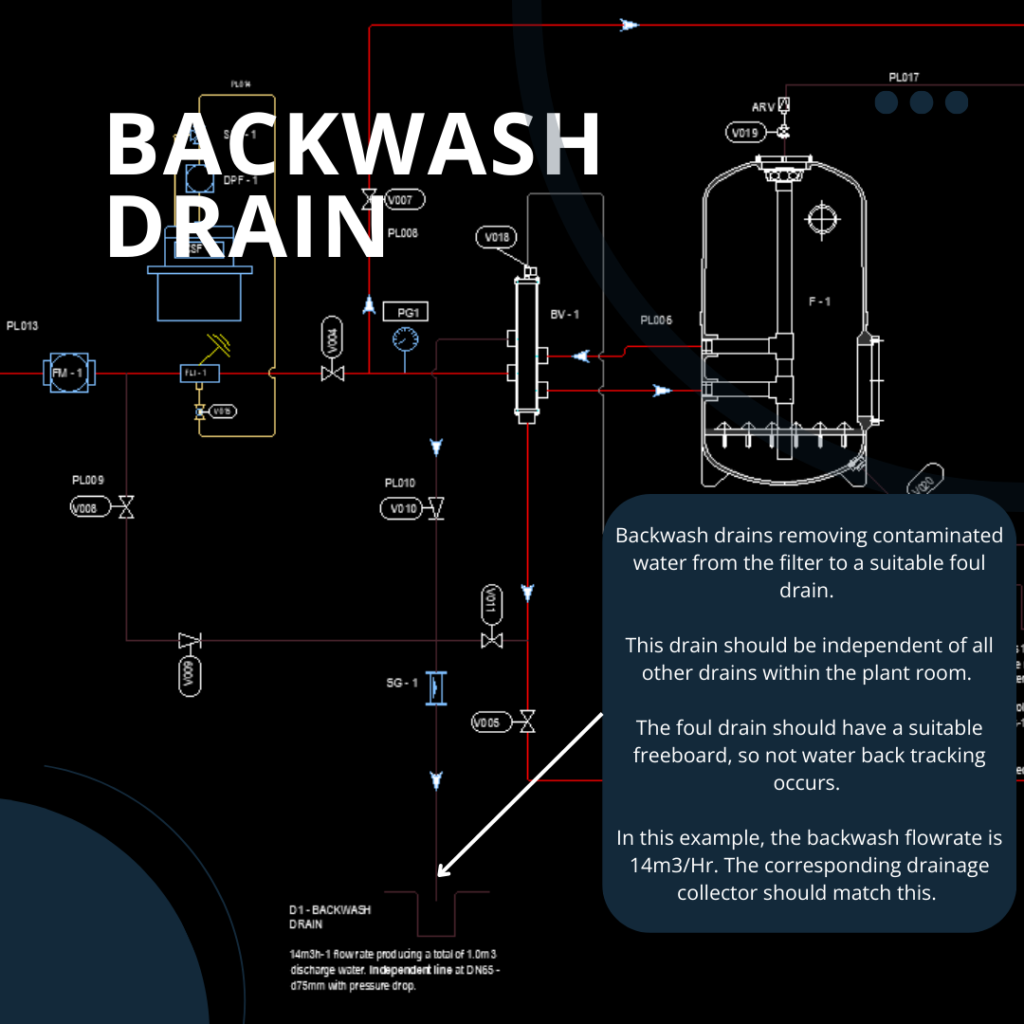

Let’s start off with arguably the most important drain – the Backwash Drainage.

Backwash Drainage

As we know, the goal of the backwash is to remove the contaminated water from the filter bed, enabling clean, comfortable bathing water.

The flow rate required to liquify the filter bed and dislodge the contaminates is higher than on a standard circulation flow rate. For a 11m by 5m domestic pool, we would expect a backwash flow rate of 16m3/h, or 267 L/m, compared to a circulation flow rate of 10m3/h, or 166L/m.

When designing backwash drainage, it is always recommended to have this drainage line independent until the drainage chamber and for the chamber to have enough freeboard to cope with this high flow rate. Otherwise, even if a non-return value has been installed on the backwash line, this waste water could track back down other drainage lines and flood connected areas – never a nice thing.

Air Handling Unit Condensate Drain

The role of an Air Handling Unit (AHU) is to control the temperature and humidity within the pool hall. We aim to maintain a relative humidity of 60%. To do this, the AHU will dehumidify the pool hall air to extract moisture. This is done in various ways depending on the make and model of the AHU.

The one thing that is common amongst all these units is that, as the air is being dehumidified the moisture extracted, the condensate, needs to be drained off. Unfortunately, it is very common for this drain to be forgotten.

A Heatstar AHU I recently specified for a project had a condensate rate of 4.9L/Hr. This is a hell of a lot of water to simply let collect all over the plant room floor. And let’s not even talk about the health and safety hazards!

Air Source Heat Pump Condensate Drain

This drain is very similar to the AHU condensate drain. I’m not going to go into massive detail about how an air source heat pump works; however, it is key to understand that a significant amount of condensate will be drained from the unit and this needs to be designed and accounted for. Having a constant wet patch on the floor under the ASHP isn’t great.

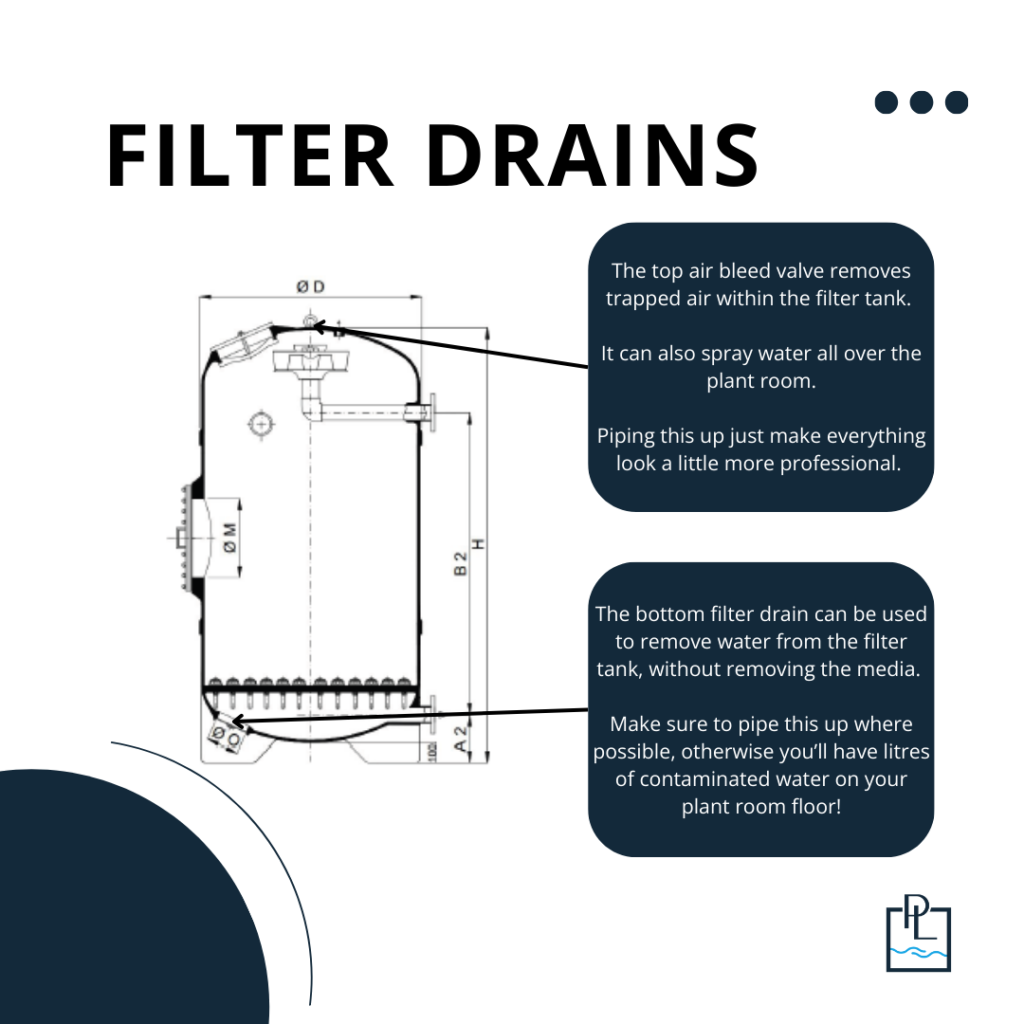

Filter Drain and Filter Air Bleed Drain

Most multimedia filters on the market have two drain points built into them: a general filter drain at the bottom, and an air bleed drain.

The general filter drain is used to empty the filter tank without removing the media. This is often used during winterisation (if the pool is outdoor), or if the filter has been damaged. A recent project of mine had a 720mm filter. When it was full of filter media, the total water volume was around 0.2m3, or 200 litres. Somehow, I don’t think draining this all over the plant room floor would be the best idea in the world.

The air bleed drain is a valve drain that is used to remove any air that has accumulated within the filtration system. You can usually see this air sat at the top of the filter just waiting to escape! Inevitably, when an air release bleed valve is open and all the air is quickly expelled, a small amount of water will also be expelled. Commonly this water is allowed to squirt all over the walls and floor of the plant room – not very professional. Whilst not catastrophic if this is neglected, simply piping this air realise valve into a waste drain line takes no time at all and will make any plant room look far more professional. (It can also be piped into the balance tank to save the water – if you’re feeling really pedantic!)

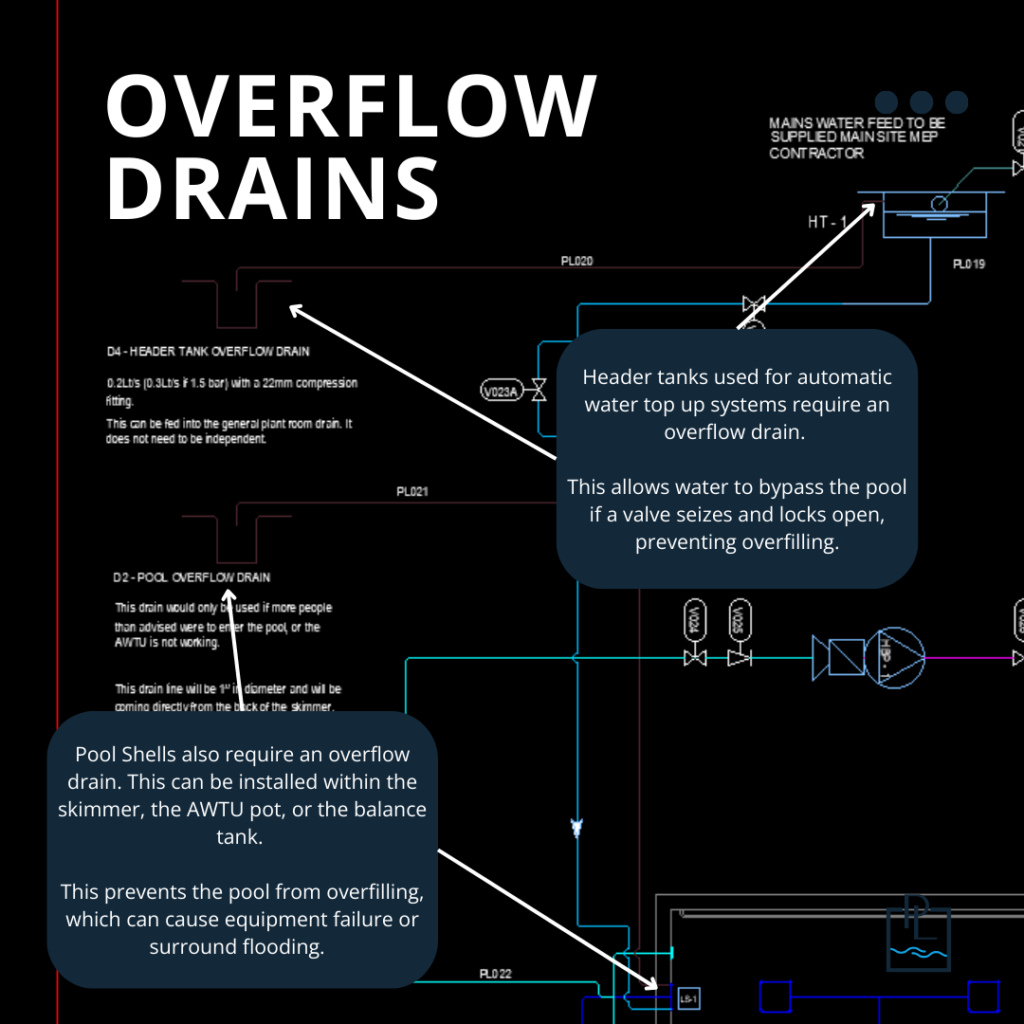

Header Tank Overflow Drain

Gone are the days when you top a pool up using a hosepipe. Every single design I complete I automatically install an automatic water top up system, even if it’s not 100% mission critical to the technical success of the project. They are super simple to install and for the total price of the entire project, they are a drop in the ocean.

However, if you are going to install an automatic water top up system, remember that your CAT 5 Type AB header tank will require an overflow drain.

In a previous life, long ago in a galaxy far far away, we received any emergency call from a client. Their plant room had an inch of water on the floor (they also forgot to install a floor drain!). This was cause because their header tank’s mains feed valve was stuck open. The header tank was therefore getting a constant feed of water but the top up valve for the pool was closed. This water had nowhere to go – so it overflowed onto the floor. Simply installing an overflow drain onto the header tank, as per the manufacturer’s instructions would have prevented all this.

Pool Shell Overflow Drain

In a nutshell, an pool shell overflow drain puts a maximum ceiling on the total amount of water that can be held within the pool system. Anything above this level and the excess amount will drain off. This is often neglected on lower valve projects but again, just like an automatic water top up system, I design 100% of my pools with an overflow drain. The benefits far outweigh the menial cost of installation. This can be installed within the pool shell, the skimmer, the automatic water top up pot, or the balance tank, depending on the overall pool construction plan.

What happens if there is a bout of heavy rain and you try opening your automatic slatted cover? It could easily become caught within the pit and get damaged.

What happens if the valve of the automatic water top up system seizes up in the open position and keeps feeding the pool with fresh water? The pool could easily overflow.

Need I say more?

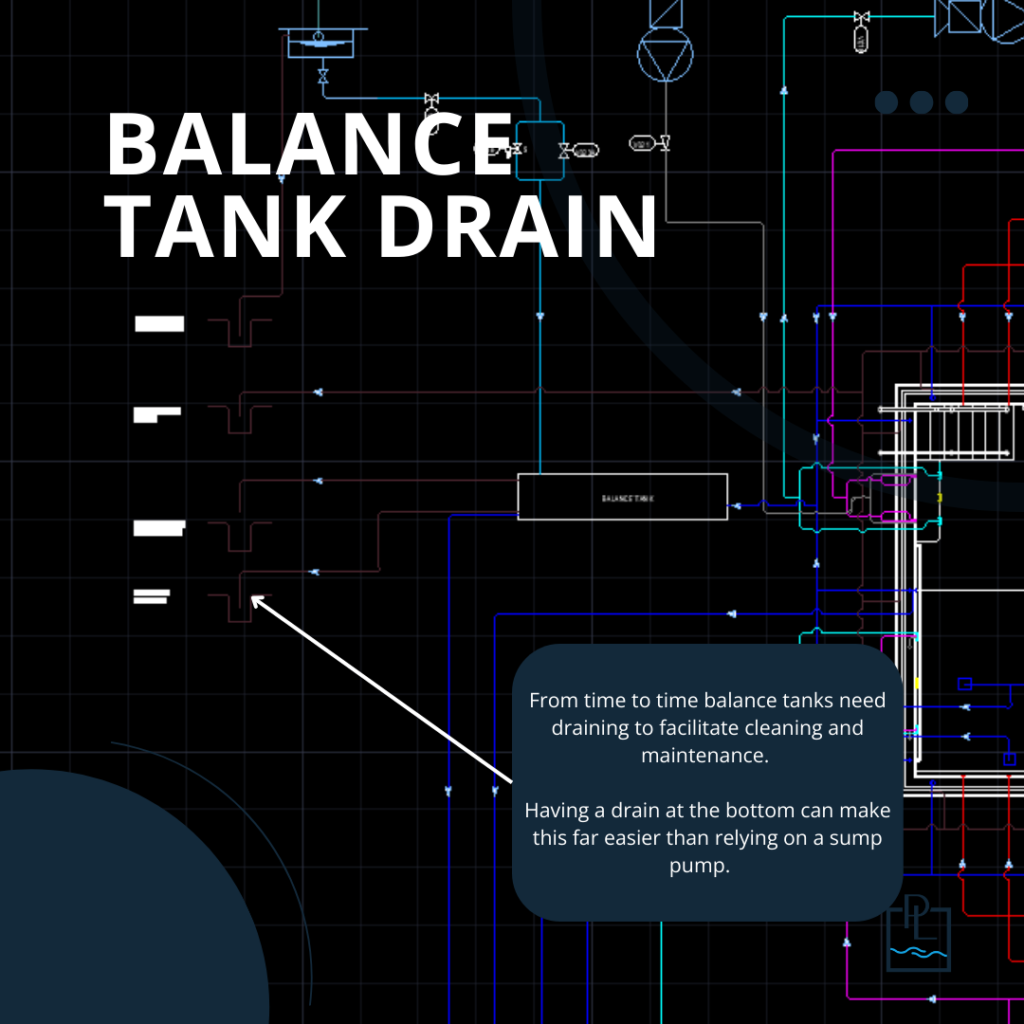

Balance Tank Drain

Balance tanks are used to regulate the water level within a deck level pool construction, amongst other things. From time to time, however, a balance tank will need to be cleaned – they are known to get a little grimy every once in a while. Instead of having to drop a sump pump into the bottom of the tank, why not plan ahead and design in a drain at the bottom.

Let’s work smarter, not harder.

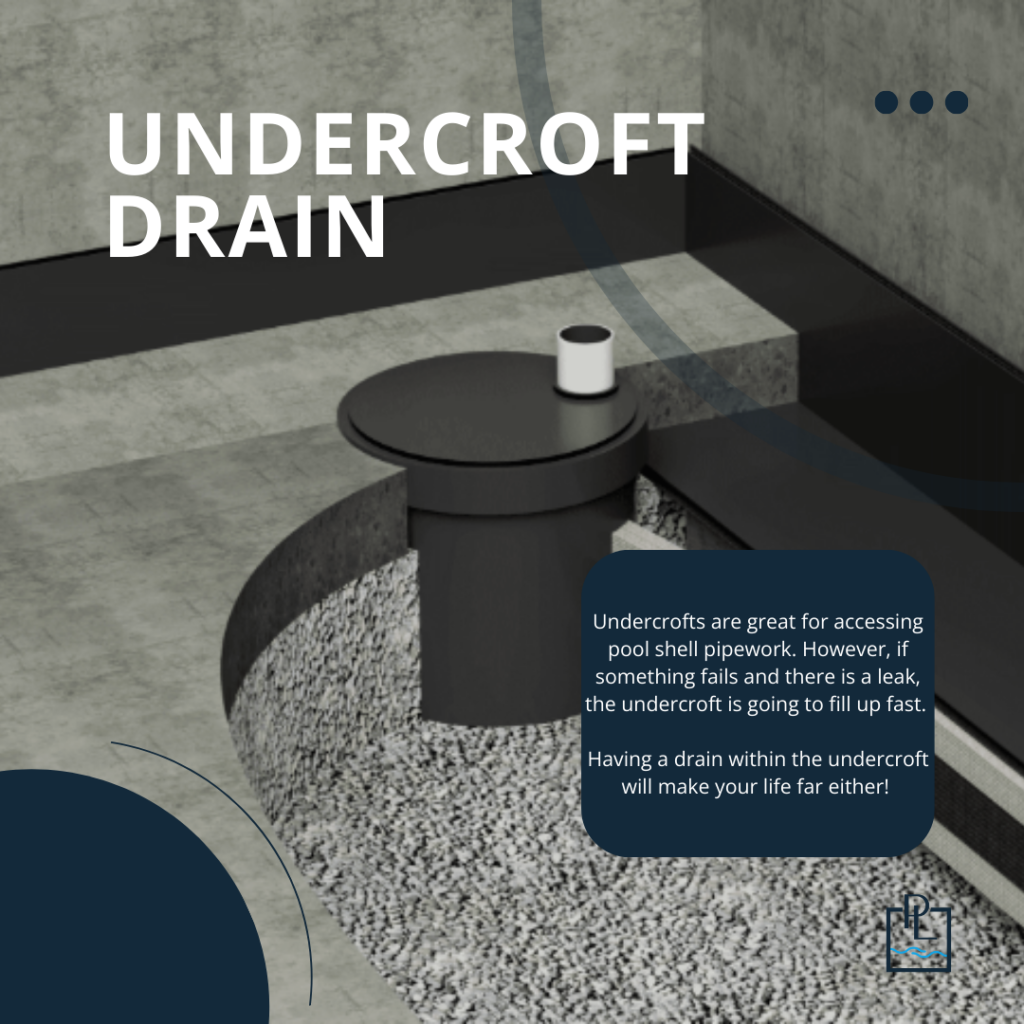

Undercroft Drain

This drain will hopefully never be used, if everything goes to plan. However, as we all know, sometimes thing don’t always go to plan.

At one of my previous workplaces, during the building process a third-party contractor damaged a few return inlet delivery pipes, yet somehow failed to make anyone else aware – they kept this quiet and didn’t tell a soul! When it came to filling the pool, these pipes failed, and the undercroft was completely waterlogged.

When this design was created the undercroft drain had been omitted, this made removing the water was a difficult and time consuming and only with the help of a puddle pump and dehumidifiers were we able to clear the problem. All this hassle could have been avoided if the undercroft drain has been added at the design stage and installed.

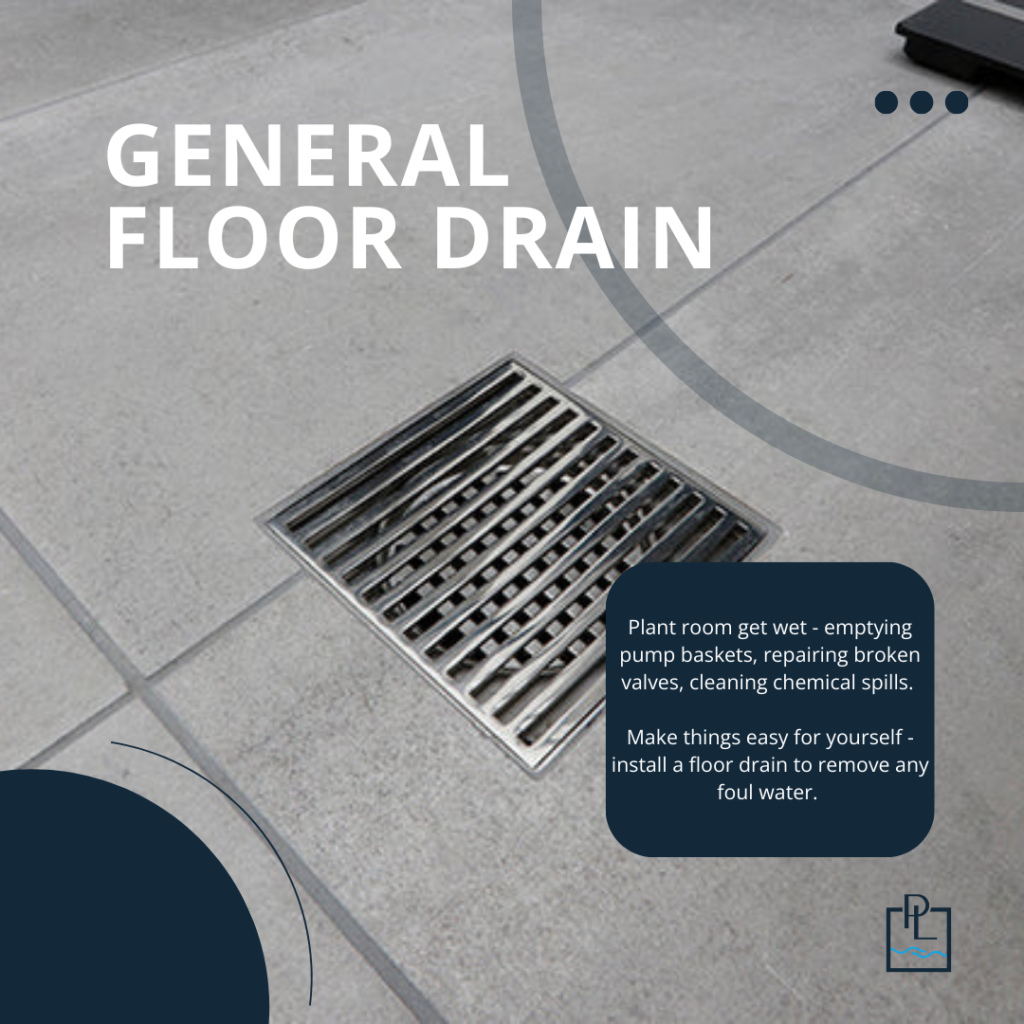

General Floor Drain

Plant rooms get wet – it’s that simple. Empty a pump basket, changing a broken valve, cleaning up a chemical spill. Don’t have things hard for yourself. Install a simple floor drain so waste water can be easily cleaned and removed. Nothing too complicated!

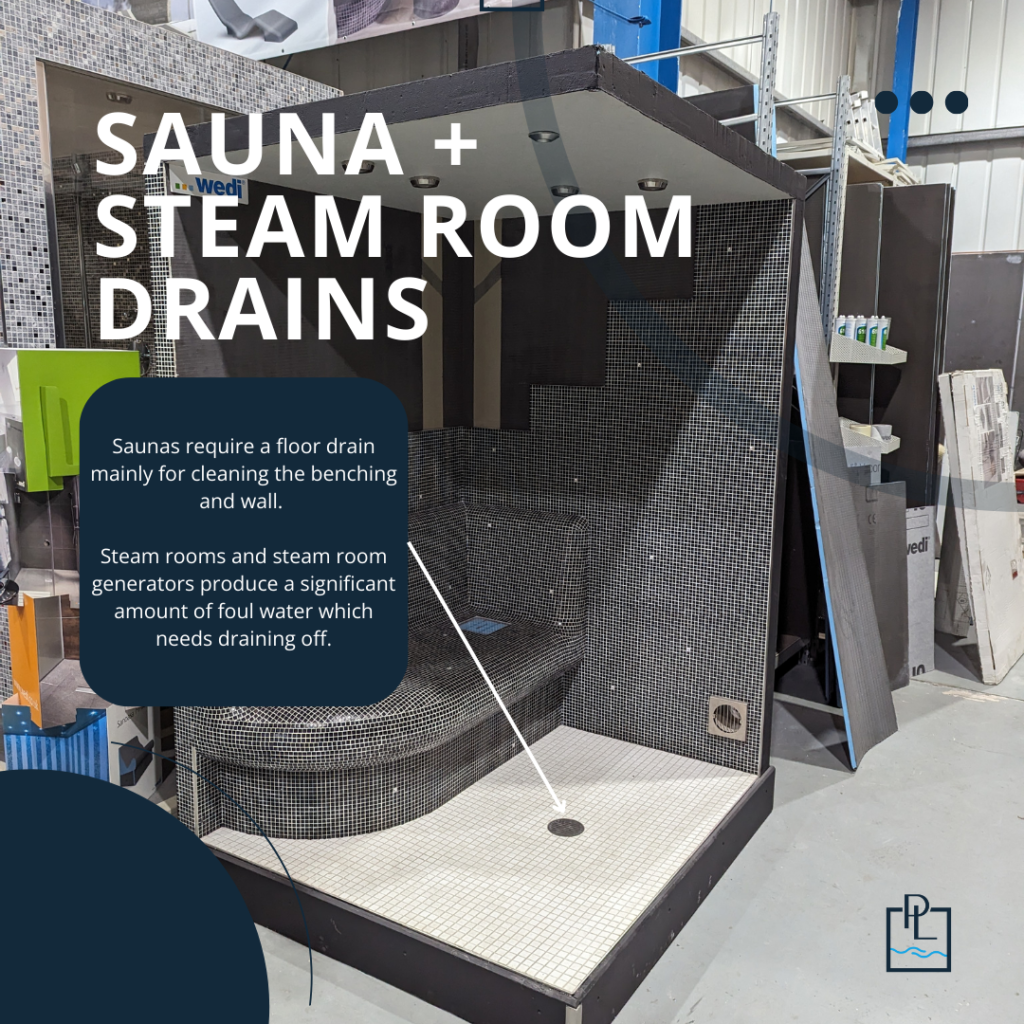

Sauna Floor Drain

Whilst not directly involved in swimming pool construction, often a sauna will be installed within the same project. And if you’re having a sauna installed, a drain is probably not the first thing that comes to mind. It’s not really known for being a wet environment; however, the drain is still very important. The drain within a sauna is used for cleaning and maintenance. Whenever your sauna benches are wiped down, this waste water needs to be able to escape.

Steam Room Drains

Again, similar to the sauna, a steam room is also often included within the full project design. Within a steam room design there should be two drains: one for the room itself and one for the steam generator. Whilst the drain inside the room is often remembered, it’s incredibly common for the steam generator drain to be omitted. This makes servicing and descaling the steam generator far more difficult than it needs to be.

As you can see, there is a lot more thought that goes into designing swimming pool drainage than meets the eye. Whilst some drainage lines are more mission critical than other, all serve a valuable function and missing one from the design can cause functionality issues down the lifespan of the pool/project.

In the next part of this series, we are going to dig a little deeper into the other services required to build a top notch pool.